Blog

11/07/2024

Transform service experiences and enable service revenue growth with connected installed base data

Manufacturing companies have hidden potential in existing deliveries. Discover how connected installed base data, product and service lifecycle management, and end-to-end customer journeys can transform your service business and accelerate growth.

Technological transformation is reshaping manufacturing. Interconnected data, process automation, artificial intelligence, and seamless system integration are at the heart of this transformation. This might sound like hype, but these aren’t only buzzwords; they are the building blocks of a new digital landscape in manufacturing.

Manufacturing companies have huge hidden potential in existing deliveries. In this blog, discover how connected installed base data, product and service lifecycle management, and end-to-end customer journeys built with the help of the data, process automation and AI can enable your service business transformation and accelerate growth. Learn how this can be achieved with technology like Salesforce Manufacturing and Data Clouds.

Benefits of installed base data

From a business perspective, it’s important to ask yourself if your company could utilise installed base data to improve its operations. According to my experience, for most manufacturing companies the answer is yes. Many companies don’t utilise the full potential of the installed base.

Another question is how Salesforce solutions, like Data Cloud, Manufacturing Cloud, and AI, could speed up the transformation.

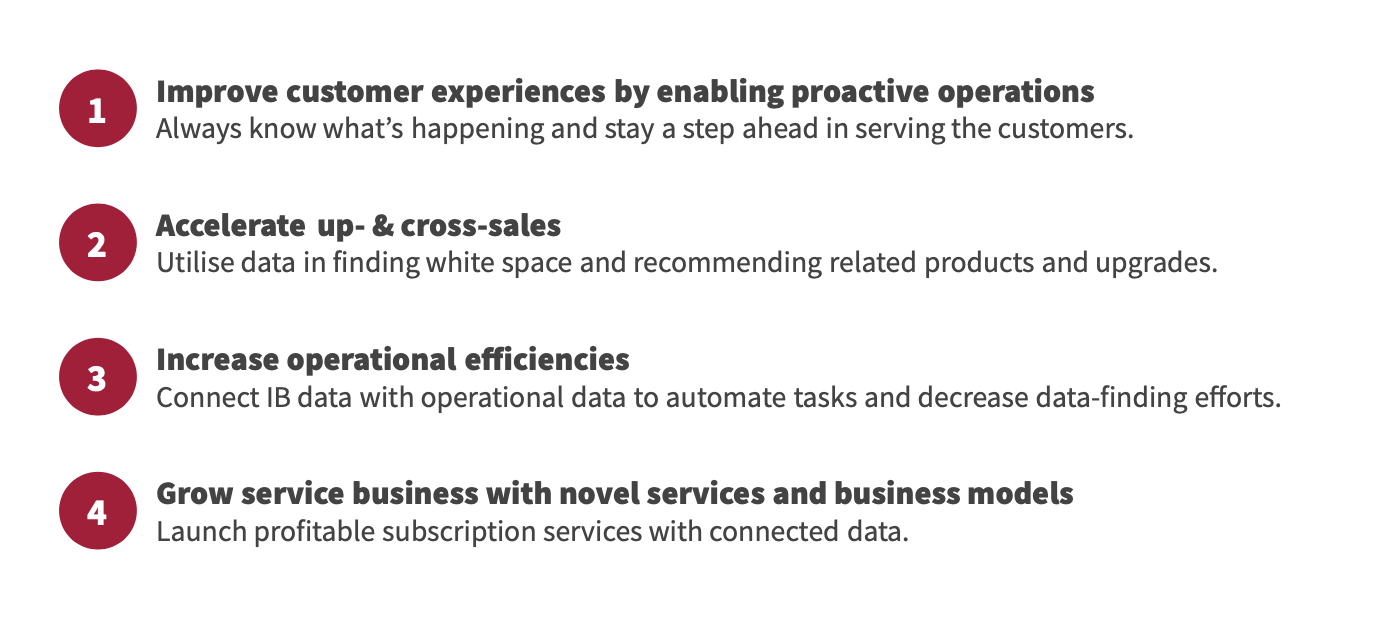

Let’s take a look at what this could mean in practice. If you would like to:

Outstanding service

Every manufacturing company wants to enable proactive service operations (and many are already doing this). Benefits of proactiveness include increased customer satisfaction and the possibility to bill customers for always being a step ahead and keeping their equipment uptime at record levels.

To do this, you must have installed available base data and a real-time connection to the equipment. However, the relevant data must be available in the interaction systems, such as customer service systems and customer portals, to serve customers better. When having data in place and connected, you can provide tailored experiences across the journeys in all the moments that matter.

Increased sales

Furthermore, companies usually have huge amounts of deliveries in the field – and every day more are started. Opportunities for up-sales and cross-sales are thus twofold: with a connected offering, you can ease the sales efforts for relevant service products together with the initial delivery. On the other hand, proactively offering the customers new products at different touch points enables you to build on the existing deliveries.

To get started with this, foundations must be in place. Your product portfolio structure must support recommending customers new products based on the purchase history and combining this with other parameters such as industry, segment, and customer size to recognize new opportunities.

In the age of high inflation and staggering demand, increasing operational efficiencies is a never-ending theme: how could you provide customers with the same or better service levels with lower costs? You could decrease manual efforts and reduce service lead times significantly by automating tasks, scheduling operations, and utilising related data. But again you need to have the connected data to achieve this.

New services and business models

Connected data and AI enable new business opportunities and models as mentioned above. Some services that can benefit from connected data might not even be possible with today’s systems – or at least would be costly to maintain. Here lies a great opportunity for competitive advantage: by investing in technology, you can launch new products and services while maintaining or improving profitability. I’m sure you want to do this before competitors do.

Novel services and business models such as remote troubleshooting, outcome-based service agreements, and uptime guarantees might not be economically viable to sell and/or produce without having data foundations and process automations in place, as you’d need to deliver the services and handle downstream processes such as subscription provisioning and invoicing manually.

Data is behind almost everything. In addition to improving customer experiences, it can boost the bottom line by increasing efficiencies and cutting costs. Next, let’s dig deeper into how you can make this happen.

Transforming installed base enabled service

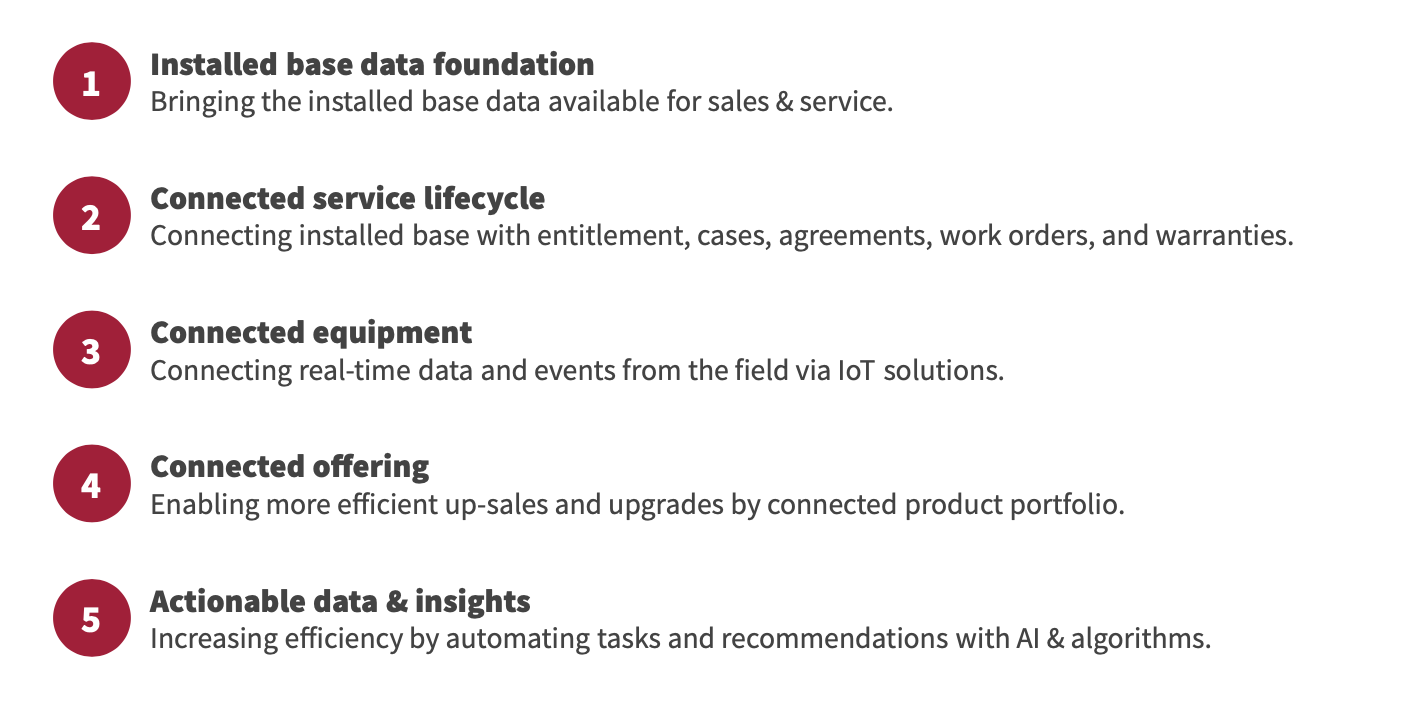

The journey to the installed base-enabled service operations might seem like a long road if you are still in the beginning. However, you can cut the elephant into smaller pieces and gradually deliver value in every step of the transformation, where the installed base data foundation is always at the core. You can flexibly decide what comes after based on your business targets. The presented steps are just an example of how to get started.

Most of the manufacturing companies I have been working with have already started this journey. Many have already connected parts of the service lifecycle and are thinking about connecting the equipment and offering and thus are in steps 3 and 4. Some are still working with the data foundations to enable more efficient service lifecycle operations. However, there is still a lot of potential in the industry to improve in all of these themes.

Installed base data foundation

Installed base data foundation is at the heart of all the related operations. It means having up-to-date data on the equipment available for all internal stakeholders and customers alike.

If the data is scattered, this might be a big ask. I recommend drawing the line somewhere in case there are a lot of existing deliveries in the field. You can ask yourself if it makes economic sense to try to gather data from very old deliveries, or should you limit the scope of the data to, for example, deliveries up to 10 years ago? Back then the systems were already more mature and the state of the data might make this achievable.

You can also consider the level of the data: should you connect the sales Bill of Materials (BOM) level of the equipment, or also dig deeper into the service BOMs? While the first option enables many of the sales and service-related operations, the latter opens up new opportunities for field service ops. From the solution point of view, you can utilise Salesforce Data Cloud to tie the equipment data from multiple systems to one unified installed base library. You can then expose it to the users with Manufacturing Cloud Asset Console and in later stages connect the live data to form the full equipment view in the main system of interaction.

Connected service lifecycle

Connected service lifecycle might sound like a buzzword, but it bears a very practical meaning: when the installed base data foundations are in place, one can start building the data infrastructure around it. You can, for instance, connect entitlements for contact centre operations, service schedules for maintenance planning and resourcing requirements, and parts for field service execution.

Getting started with SLAs and maintenance plans is low-hanging fruit, fully automating the operations is a bit longer project, also requiring organisational transformation. Typical with the companies I’ve been advising is that many of these operations are already partially in place, but the issue is that the data and execution are scattered across different CRM, Service, and ERP systems hence the life cycle is not connected. Here Salesforce Service Cloud and Field Service Lightning come into the picture connecting the customer’s business and operations to the installed base data.

Connected offering

The connected offering is the key foundation for enabling up- and cross-sales and personalised marketing opportunities. Connected offering means, for example, the ability to provide recommendations on the optimal services or related products in all stages of the customer journey: starting from the initial sales when sales reps might be using CPQ to quote products and services to customers, continuing to daily engagements where service agents and reps meet customers, or customer visits a self-service portal.

By connecting the customers’ installed base to the products from which they originated, and further the products to corresponding customer segments, you can build tailored and dynamic recommendations and guided selling experiences. You can achieve this by integrating product-to-cash solutions using Revenue Cloud solutions such as Salesforce Revenue Lifecycle Management (RLM) for the core processes and B2B Commerce for customer self-service.

Actionable insights

In the end, after you have connected customers, their business, installed base, and products, you are ready to provide actionable insights based on this data. You can then use those insights in any relevant processes, such as triggering service events or cases via Salesforce Service Cloud and Asset Console, or marketing journeys via Salesforce Marketing Cloud. Here you are really on the brink of a revolution!

There are multiple ways to achieve this end-to-end process. Currently, the predominant way is defining algorithms to generate insights and actions. However, I anticipate that going forward some years, you can build predictive logic with a combination of predictive and generative AI to achieve the same or better outcomes. Although the end state might seem far, taking the first steps to generate actionable insights can be fast. For example, think about covering the most important 20 percent of use cases to produce 80 percent of the value.

How to get there

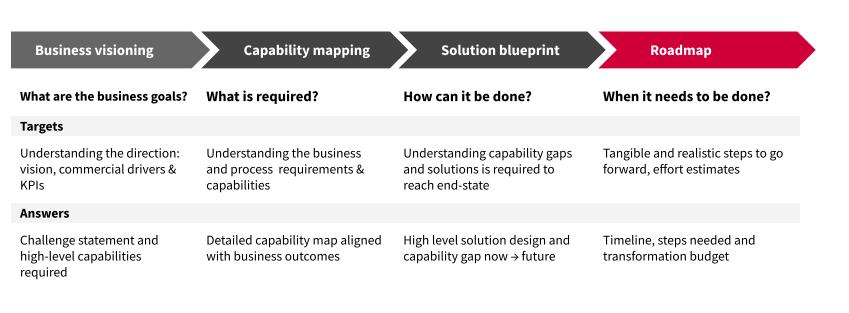

You might wonder how to get started with all this. There’s never enough time to keep the current operations running! But this is a wasted opportunity, keeping up the current inefficient, manual operations-based processes and systems instead of taking a few months to improve the situation and then saving a lot of time and effort while also increasing sales and providing superior customer experiences. Fortunately, we at Fluido can help in taking all of these steps from visioning to execution.

When it comes to transforming the business, well-planned is half done. Setting the targets and vision are the most important steps of the journey. Only when it’s clear what to do and why you can plan and prioritise effectively. See the table below for some preliminary questions to ask. If the answers to these questions are unclear, we can help you get there with our Strategic Advisory services.

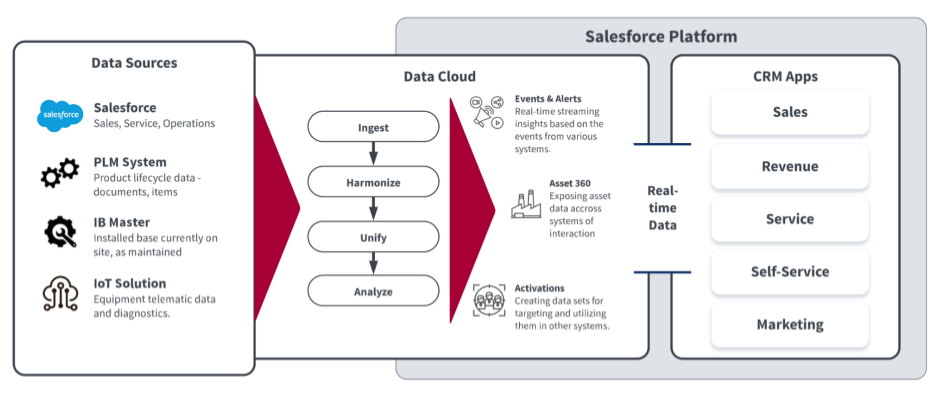

Most likely you are also eager to hear which technology or solution can make this happen. Unfortunately, I don’t have a universal answer to that. However, with Salesforce Manufacturing and/or Data Clouds you can get an accelerated start to the transformation. Following high-level architecture is something I’ve discussed with many of our customers and it always spans a great interest.

The installed base is a key element for expanding the services business and building new and sustainable business models. The possibilities are enormous when unifying installed base data from all the relevant systems, bringing it together to Customer & Asset 360, exposing it to interaction systems, and making it actionable while providing real-time insights and actions to Salesforce and downstream systems. With Manufacturing Cloud Data Packs launched in the Salesforce Summer ‘24 release, we can get you started fast.

If you have any further questions you can send me a message or contact our sales. Or if you have any specific topics you’d like to hear more about, I’m happy to have some feedback.

Santtu Kumpulainen

RLM Practice Lead & Architect at Fluido

Read next

22/07/2024